Passavant® CENTRE-FLO™ Band Screen

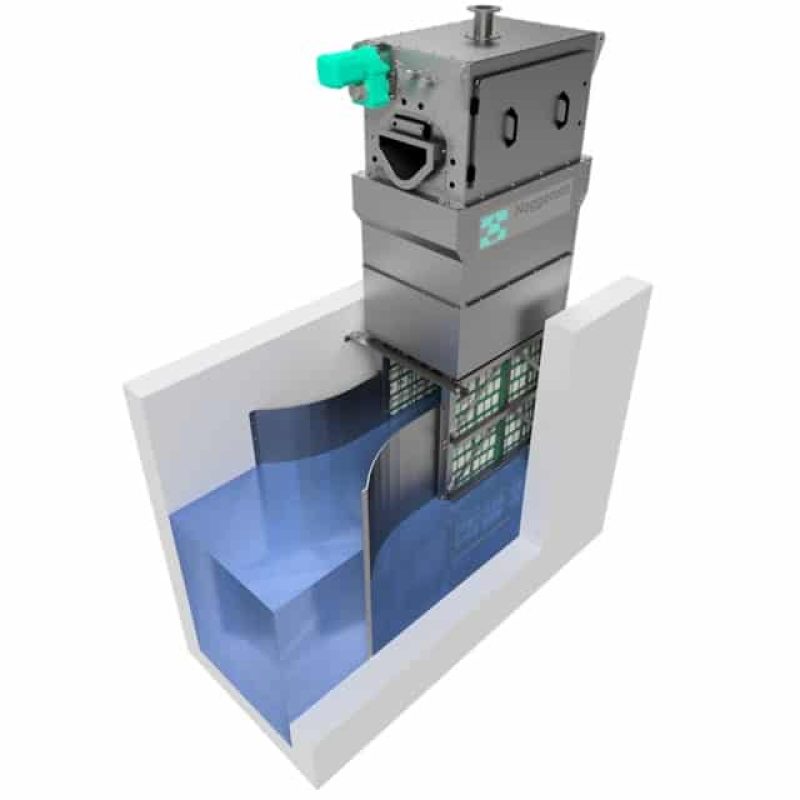

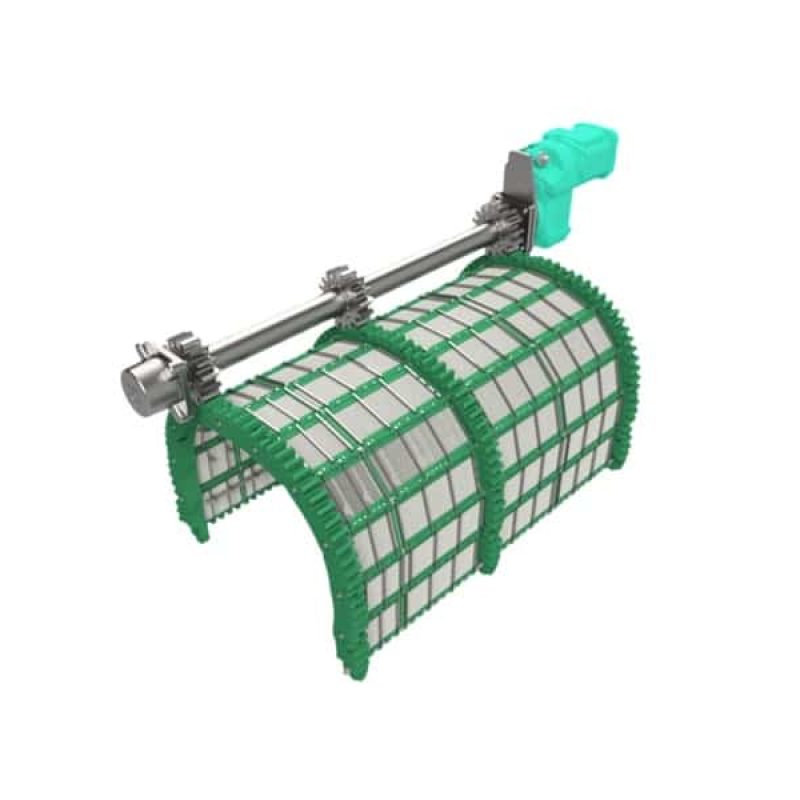

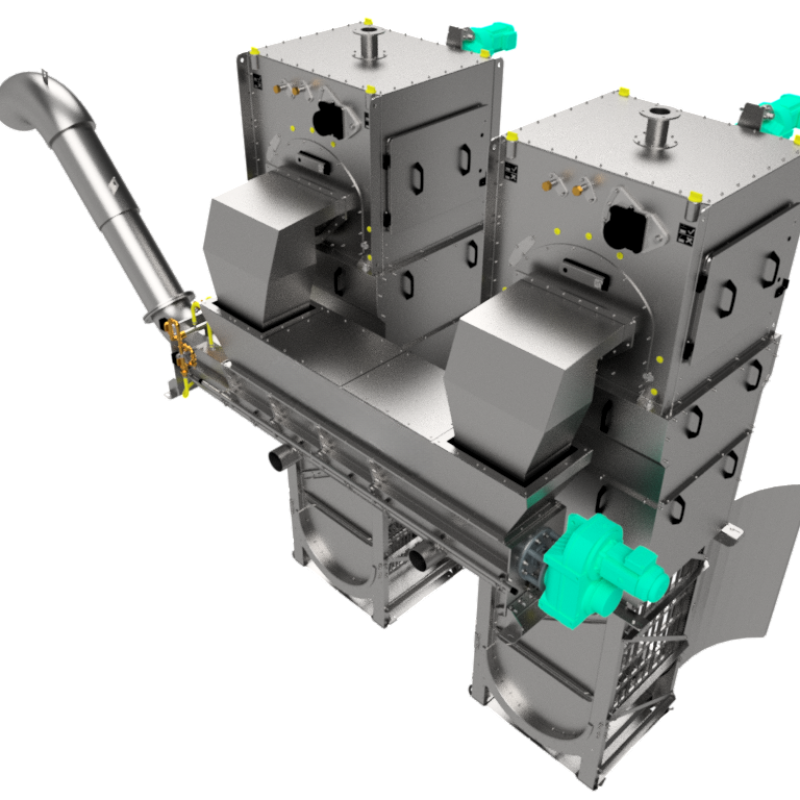

PASSAVANT Centre-Flo™ Band Screen offers an efficient, space-saving screening solution featuring a revolutionary drive concept. Unlike conventional systems, the Centre-Flo employs a chainless drive with shaft and pinion positioned on the clean, exterior side of the screen belt.

The geometry of the screen belt and the large open area of the panels deliver a high capture rate of screenings. The clean side and dirty side are strictly separated, effectively eliminating any “carry-over” of solids to the clean water side.

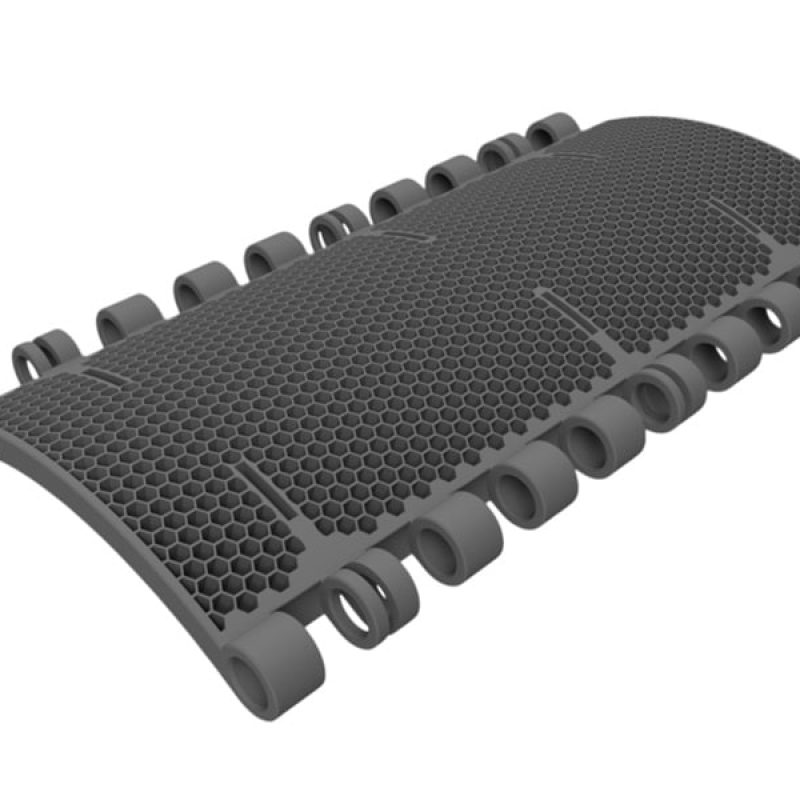

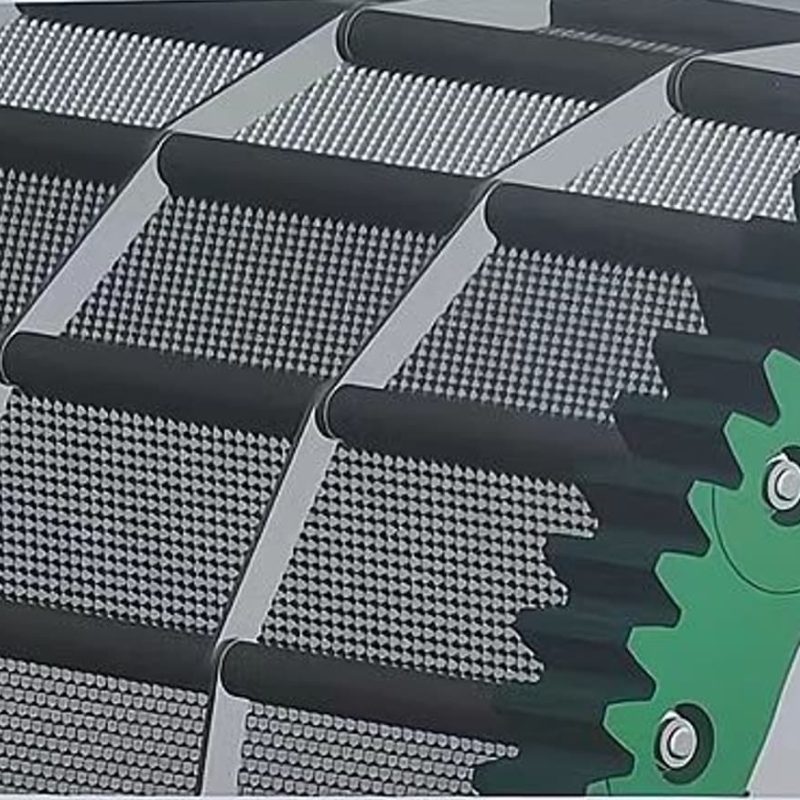

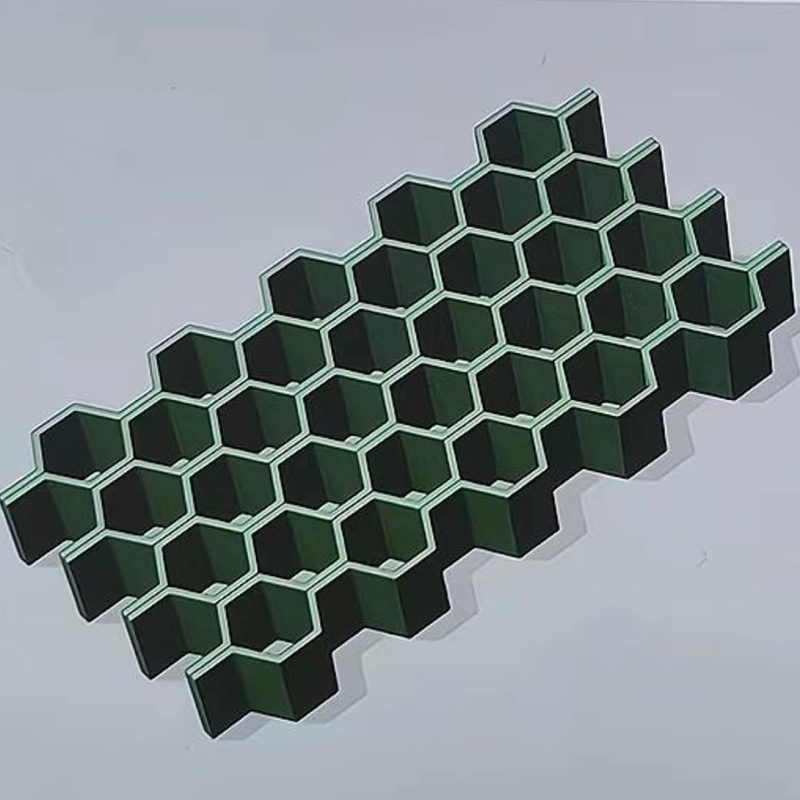

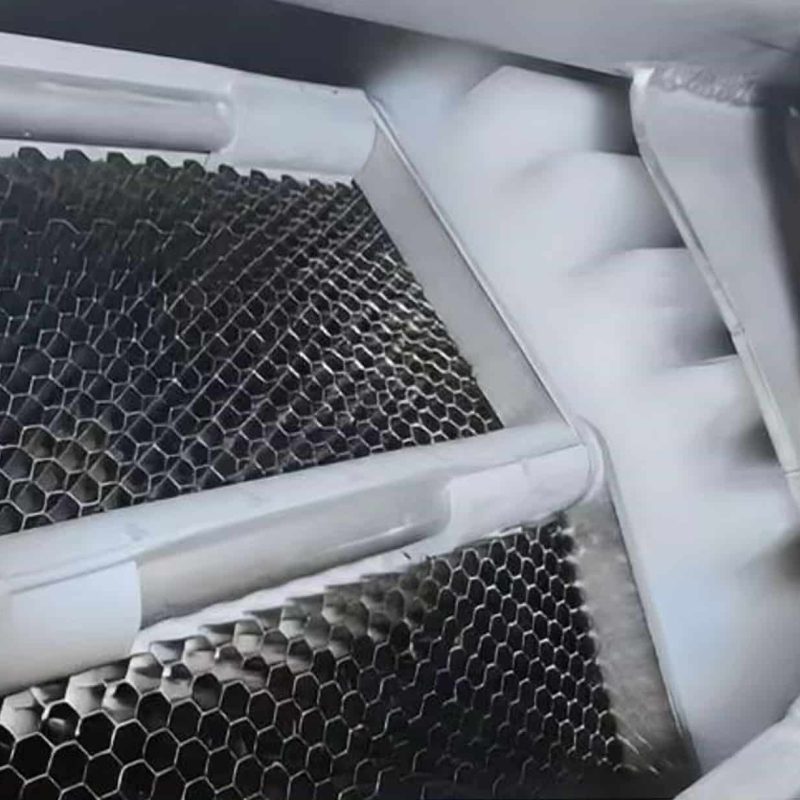

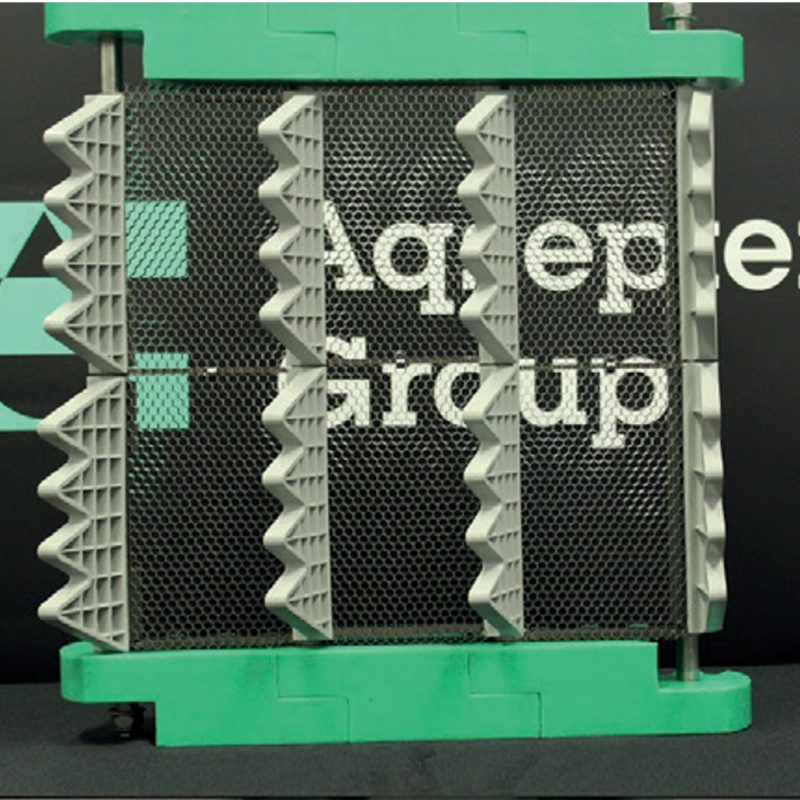

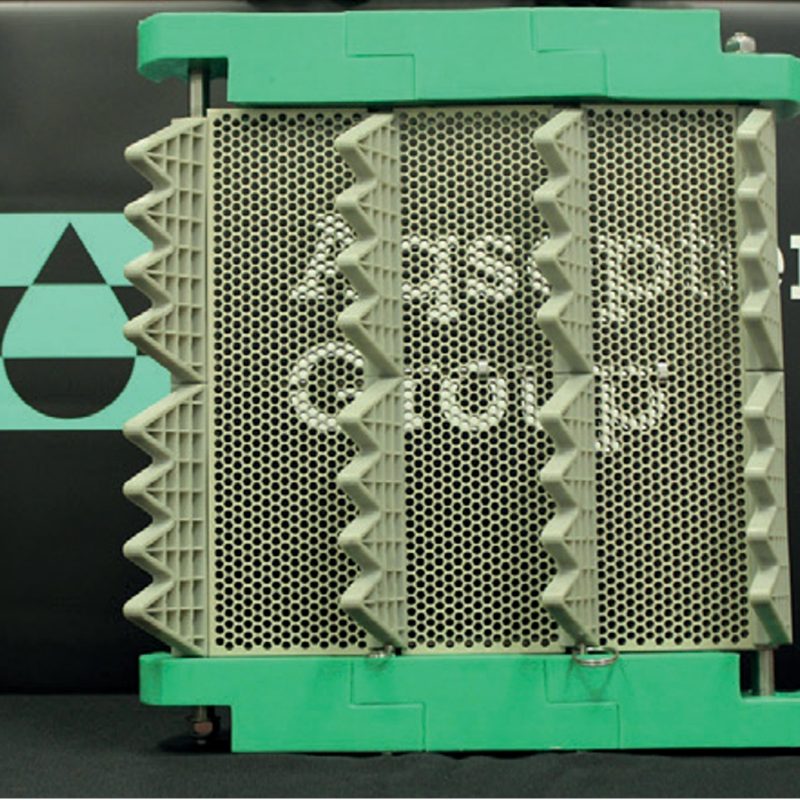

With its curved honeycomb panels, Noggerath® delivers outstanding performance in wastewater treatment. Additionally, there are further innovative screening options such as flat honeycomb panels and perforated panels. Both types are available via additive manufacturing (recommended) or in stainless steel, if preferred.

Inspired by natural geometry, the honeycomb screening elements provide an exceptionally high open area—up to 90%—resulting in reduced headloss and significantly increased hydraulic throughput.

The diverter plates guide the influent water into the submerged section of the screen, where the flow undergoes a 90° directional change and passes through the Centre-Flo™ screening panels. The large open area reduces head loss and increases hydraulic throughput. Solids are captured on the inner surface of the filter panels, especially effective for fine and fibrous material, and accumulate over time.

As upstream water level rises and reaches a preset threshold, the screen activates. The screening panels begin rotating, lifting the retained solids upward. Larger particles are conveyed by lifters to the discharge point. At the top turning position, a wash water system flushes the panels from the outside, ensuring a full 360° cleaning. This design ensures high screening efficiency, minimal carryover, and consistent performance. The screen continues to operate until the water level drops back to the lower setpoint.

Key Features

• Modular design allows customization of screen height and channel width based on headloss, flowrate, and installation constraints.

• Patented honeycomb panels with up to 90% open area deliver superior hydraulic capacity—20% to 40% more than traditional perforated plates.

• Unique vertical slot arrangement maximizes filtration area and simplifies future screen upgrades or panel replacements.

• Robust submerged structure design with all components made from high-grade corrosion-resistant materials; ideal for harsh wastewater environments.

• External drive system eliminates dead zones and internal jamming risks.

• Optional dual spray bar system improves cleaning while reducing water use and operational cost.

• Safety guards over access points or inspection covers ensure reliable protection.

• Centre-Flo™ screen can be integrated with various solids handling systems such as compactor washers, conveyor screws, and press systems.

• Flow diverters in front of the screen guide excess water directly into the top of the screen, eliminating the need for bypass troughs.

Technical Data

| Design Sizes & Performance | |

|---|---|

| Flowrate [l/s] | 200–5,000 |

| Channel width [mm] | 700–2,400 |

| Channel depth [mm] | up to 10,000 |

| Opening – Curved honeycomb panels (standard) [mm] | 3–6 |

| Opening – Full bore perforation (option) [mm] | 1–8 |

| Opening – Flat honeycomb panels (option) [mm] | 1–10 |

| Screenings capture rate | up to 92% |

| Materials | |

| Frame, Encapsulation | Stainless steel AISI 304L or AISI 316L (others on request) |

| Drive guide links | UHMWPE, oil-impregnated |

| Panels | Polypropylene, or UHMWPE, or stainless steel AISI 316L |

Need Custom Configuration?

Our engineering team can customize this equipment to meet your specific requirements. Contact us for detailed specifications and pricing.