Passavant® DUODRAIN Combined Sludge Thickening and Dewatering Machine

The DUODRAIN system is a compact solution that integrates the

ROEFILT drum thickener and ROEPRESS belt filter press, designed for municipal and industrial sludge of varying compositions and concentrations.

- Thin sludge can be thickened and dewatered directly—no static pre-thickening required.

- Thickening only mode is available, with no further dewatering.

- Thick sludge can bypass thickening and go straight to dewatering.

- Operation modes can switch flexibly as needed.

By combining both functions in one unit, DUODRAIN helps reduce footprint and simplifies system control.

Thanks to its dual-function design, only one set of ROEDOS flocculant dosing system, one control panel, and one feed pump are needed for either mode.

In thickening mode, concentrated sludge is discharged via a pump. If dewatering is required, sludge continues to the press section for high-solids cake formation.

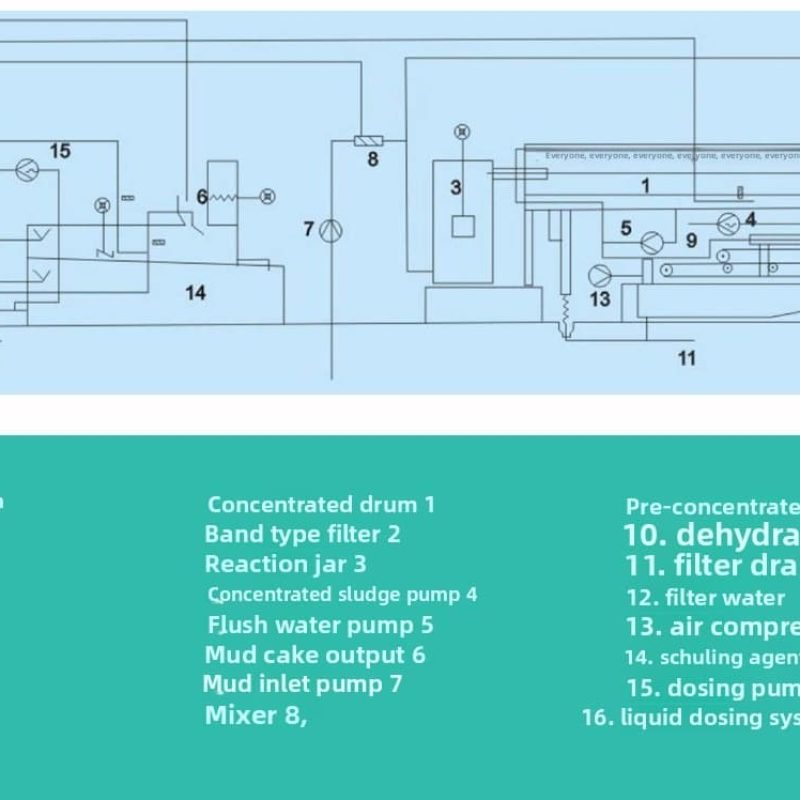

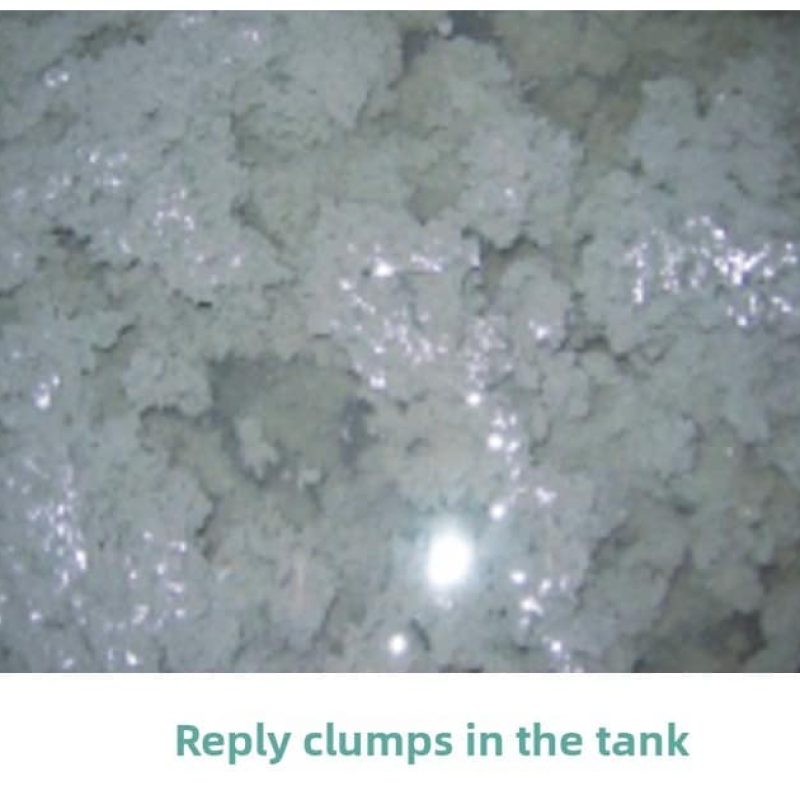

DUODRAIN operates based on the principles of gravity drainage and mechanical pressure filtration. Polymers are added to the feed sludge via the ROEDOS flocculant dosing system and are rapidly mixed using inline mixers. The flocculated sludge then flows into the flocculation reactor, where under laminar conditions, floc formation occurs. From there, the flocculated sludge enters the ROEFILT drum thickener inlet, where a sludge roll begins to form.

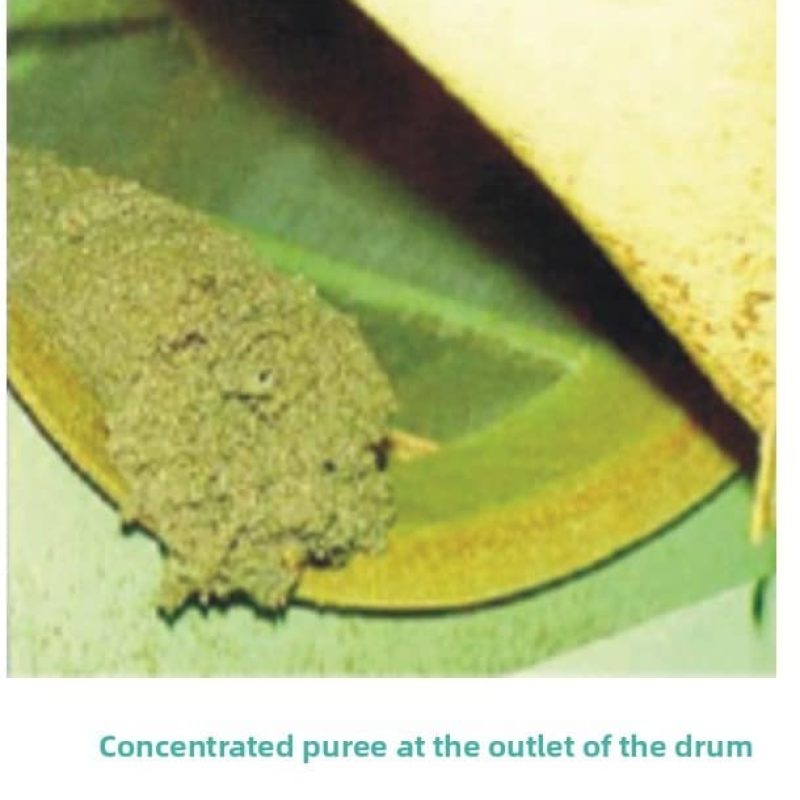

Water in the sludge is separated through gravity and drained through the filter mesh. The clean filtrate is reused as spray water to clean the filter fabric. As sludge progresses through the drum, a helical screw conveys the increasingly thickened sludge toward the outlet. It is then discharged either to a belt press or via a sludge pump. The ROEPRESS belt filter press dewaters the sludge in three phases: (1) gravity drainage zone between upper and lower belts; (2) wedge zone with high-pressure rollers applying strong compression and shearing force; and (3) S-zone where residual water is removed under alternating tension, producing a high-solids cake ready for discharge.

Key Features

- Flexible polymer/sludge ratio control ensures optimal flocculation performance.

- Oversized filter drum design compensates for fluctuations in sludge flow and concentration.

- Independent speed control for drum and filter belt enables adjustment based on feed conditions.

- Thickened sludge can be directed to the belt press or discharged via pump.

- Automatic spray system cleans the drum and belts at set intervals.

- Separate filtrate collection for thickening and dewatering zones; filtrate can be reused.

- Pneumatic belt tensioning system ensures accurate pressure control and operational stability.

- Belt alignment automatically corrected with sensor feedback to prevent deviation.

- Gradually decreasing roller diameters enhance gravity pressure and cake dryness.

Technical Data

| Design Data & Performance | |

|---|---|

| Input DS concentration (thin sludge) | 0.5% – 2% |

| Final DS concentration after dewatering | 15% – 20% |

| Volume reduction (thin sludge) | 1/30 – 1/40 |

| Input DS concentration (digested sludge) | 2% – 6% |

| Final DS concentration after dewatering | 30% – 40% |

| Volume reduction (digested sludge) | 1/15 – 1/20 |

| Solids capture rate | Typically around 99% |

Need Custom Configuration?

Our engineering team can customize this equipment to meet your specific requirements. Contact us for detailed specifications and pricing.