Passavant® Roepress Belt Filter Press

ROEPRESS Belt Filter Press offers a cost-effective, automated, and efficient sludge dewatering solution for both municipal and industrial wastewater treatment plants. With its robust structure, low chemical and energy consumption, and excellent solids capture rate of up to 99%, ROEPRESS ensures optimal performance across various sludge types and operating conditions.

ROEPRESS integrates a large pre-dewatering drum and dual belt system to reduce water content at each stage. Its smart flocculation control, self-cleaning system, and fully automatic operation minimize manual intervention, reduce running costs, and deliver consistently high cake dryness — making it ideal for new installations, plant upgrades, or mobile sludge dewatering units.

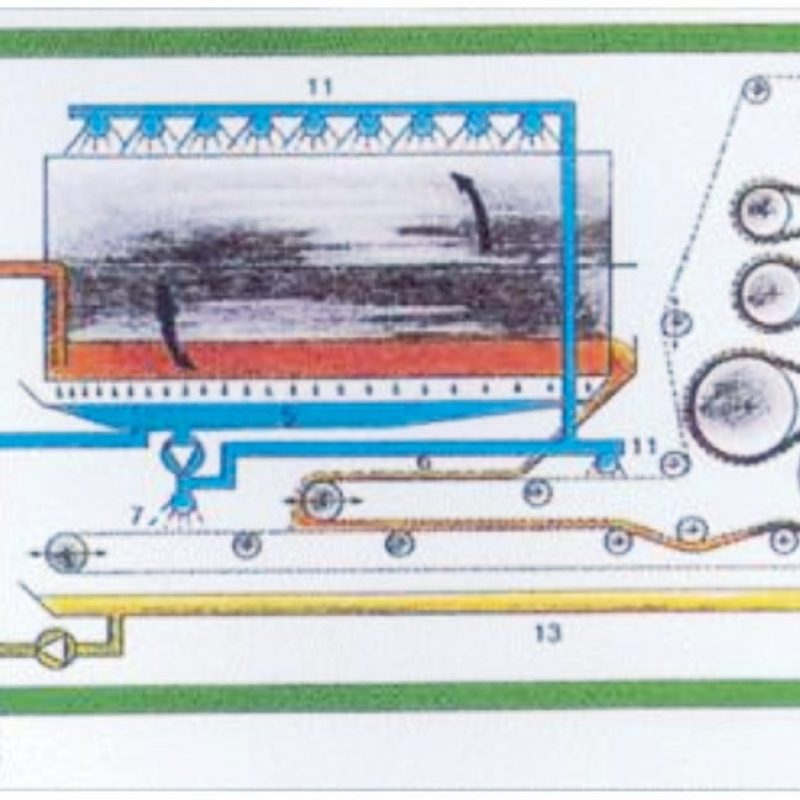

Sludge (1) is mixed with flocculant solution from the dosing unit (2) in an inline mixer (3). The flocculated sludge flows into the slowly rotating pre-dewatering drum (4).

As the sludge is conveyed to the discharge end of the drum (4) via the screw shaft, a large portion of free water is released through the screen and collected in the filtrate tank (5).

At the end of the drum, the pre-dewatered sludge slides down a chute onto the upper filter belt (6), then flips onto the lower belt (7). The sludge structure becomes visible on the belts (6) and (7), helping operators adjust polymer dosage precisely with minimal experience.

The sludge is then conveyed through the low-pressure zone (8) and into the high-pressure zone (9), where it is gradually dewatered under increasing pressure and shear force. Finally, the dewatered sludge is discharged at outlet (10).

Filtrate from the pre-dewatering drum is collected in the tank (5) and sprayed onto the belts using spray nozzles (11). Highly contaminated filtrate and wash water gathered in tank (13) are returned to the sludge inlet pipe (12) and reprocessed in the drum (4).

Key Features

- Large pre-dewatering drum allows gentle floc separation and reduces load on the press zone.

- Stepped pressure and shear zones ensure high solids content in the final sludge cake.

- Self-sufficient spray system uses recycled filtrate to clean belts and drum, minimizing water consumption.

- Minimal external water required — only needed during machine startup and occasional post-cleaning.

- Fully automatic operation including start/stop control, belt cleaning, and fault shutdown logic.

- Pneumatic belt tensioning ensures uniform pressure and prevents belt wrinkling or misalignment.

- Open-frame construction allows easy access for operation, maintenance, and cleaning.

- Modular system allows special configurations such as DUODRAIN or ROEPRESS-OT for sludge-specific needs.

- Mobile version (ROEPRESS MOBILE) available — compact, transportable, and operable in temperatures down to -15°C.

Technical Data

| Design Data & Performance | |

|---|---|

| Input DS concentration (thin sludge) | 0.5% – 2% |

| Final DS concentration after dewatering | 15% – 20% |

| Volume reduction (thin sludge) | 1/30 – 1/40 |

| Input DS concentration (digested sludge) | 2% – 6% |

| Final DS concentration after dewatering | 30% – 40% |

| Volume reduction (digested sludge) | 1/15 – 1/20 |

| Solids capture rate | Typically around 99% |

| Belt width (max) | 2.5 m |

| Machine length | Up to 8.0 m |

| Transport speed (mobile unit) | Up to 80 km/h |

| Operating temperature (mobile unit) | Down to -15°C |

Need Custom Configuration?

Our engineering team can customize this equipment to meet your specific requirements. Contact us for detailed specifications and pricing.